-

-

88-T, 1st Floor, Civic Commercial Area, Phase 2 DHA, Lahore

88-T, 1st Floor, Civic Commercial Area, Phase 2 DHA, Lahore

In RepaCoat, DIAMANT Metallplastic offers a much tried and tested product system for wear protection and repair coatings in the demanding industrial environment.

RepaCoat from DIAMANT Metallplastic is available in three special product variants for precisely targeted use - supplemented by an optional application system for time-optimised coating:

DIAMANT moglice flexible 2-component, fast-curing coating with high resistance to aggressive loads. After curing, RepaCoat FX exhibits high resistance to abrasion and tearing as well as full reversion after being subjected to tensile or compressive loads. The special recipe with select, highly crosslinking polymers ensures reliable adhesion to metal, natural and synthetic rubber (nitrile and butyl rubber), wood, concrete, etc.

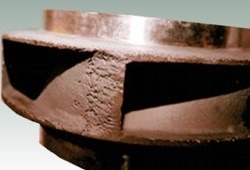

Pasty 2-component polymer material with highly wear-resistant, solid ceramic balls and special fillers. RepaCoat PH is distinguished by a good process and high stiffness. The durable coating material has proven itself above all wherever extremely high resistance to impacting solid particles in liquid media, gases and bulk materials is called for.

Liquid, cold-curing epoxy formulation with outstanding chemical resistance, achieved by the use of special resins and hardeners as well as additives and inert fillers. RepaCoat CH is particularly suitable for protection against mixtures of aggressive organic and inorganic media.

The DIAMANT Venturi Coating System is the ideal solution for applying RepaCoat coatings to medium-size surfaces. With this innovative low-pressure process the duration of the application is drastically reduced, whilst the effectiveness is increased at the same time. Hence, 23 m² can be coated effortlessly per hour with a layer thickness of 200 μm using the Venturi Coating System. Apart from the Venturi spray gun, the use of the Venturi Coating Systems requires a compressed air source of 8 bar. The RepaCoat coating is supplied in a double cartridge with a special mixing spiral for the system.